Lake|Flato, Risinger, Positive Energy, & Bensonwood

We recently took a detour from the esteemed Westford Building Science Symposium, aka “Building Science Summer Camp,” to visit our friends at Bensonwood in New Hampshire. Currently, our office is working alongside Lake|Flato and Risinger & Co. to design and build some creative, beautiful, innovative, and healthy homes using Bensonwood’s incredible production process. We were able to tour with both Lake|Flato and Risinger’s team last winter sans Mat, but luckily got to have him join us for our summer tour.

If you’ve never heard of Bensonwood before, you’re missing out. You can say that Bensonwood’s history began with New England’s building history. The pioneers of this region created durable, honestly-crafted buildings framed in heavy timbers, and held together by mortise-and-tenon joinery. This timber frame form of construction was dominant in buildings in America until the late 1800s. After that, new building methods, the westward expansion and the increasing need to build quickly, slowly led to the demise of the timber framing craft in this country.

In 1974, Tedd Benson became intrigued by these remarkable timber-framed houses and barns — many of which had stood for more than two centuries. Impressed with the durability and beauty of these structures, Tedd worked to revive the ancient craft of timber framing for contemporary homes using modern tools and methods.

His passion for timber framing quickly got the attention of the region’s dedicated woodworkers, and he formed Benson Woodworking Company. Together, Tedd and his co-workers refined the forgotten craft of framing buildings with heavy timbers for modern living. The collaboration of this group led to a series of innovative ideas; many of which are still being used today at Bensonwood. And as the company has grown, the relentless drive and enthusiasm to create better building strategies have continued.

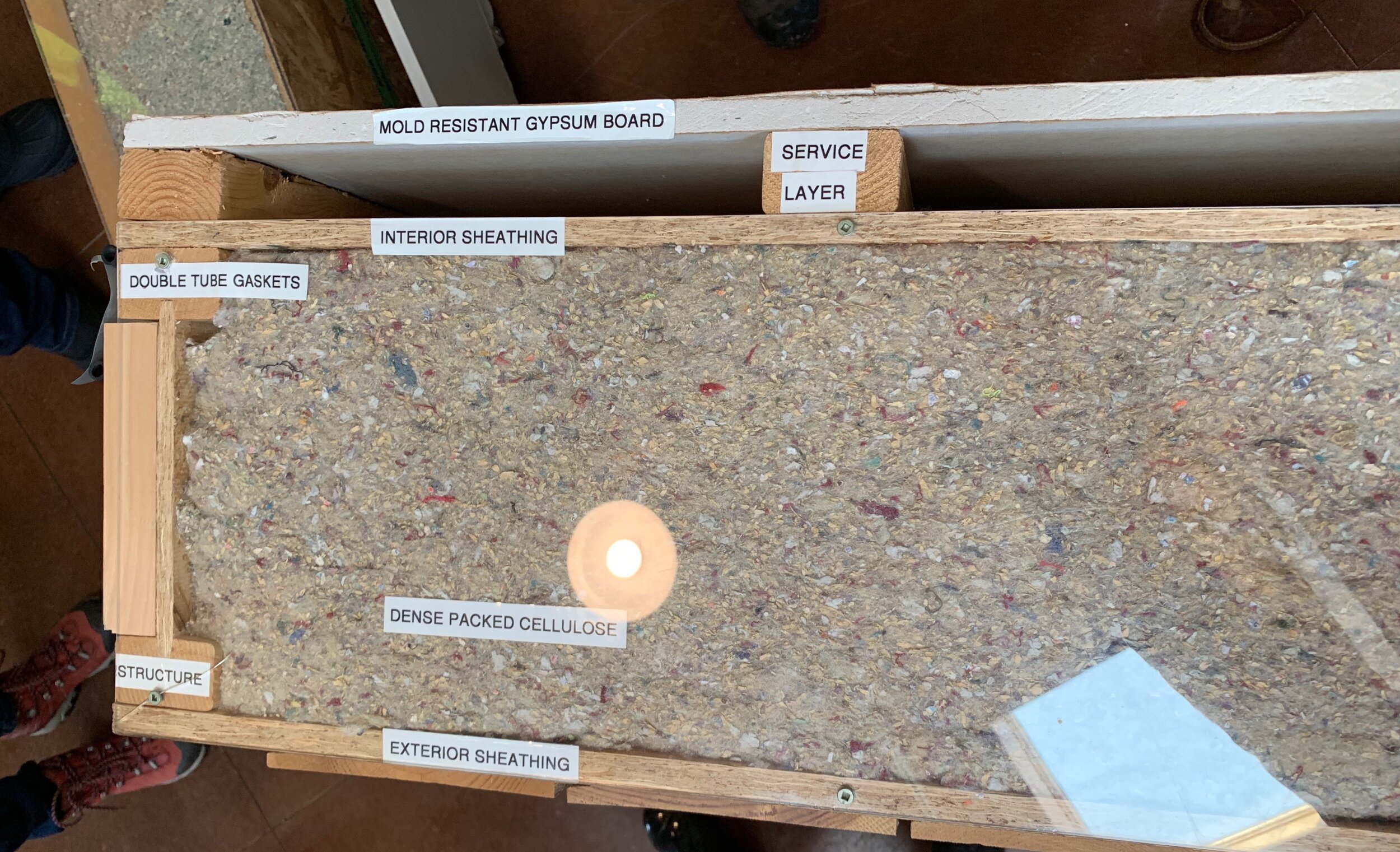

These days, Bensonwood is producing very precise off-site panelized assemblies that get turned into buildings. You can take a Revit model and Bensonwood can turn it into a built reality, which takes the time it takes to dry a house in from a few months to a couple of weeks. It’s remarkable and, in many ways, the future of buildings.

Check out Matt’s video for more details!

Pics From Both Our Summer & Winter Tours

Ted Benson showing us how window installations work in the factory.