Rethinking Moisture Control: The Primacy of Air Tightness Over an Outdated Fixation on Vapor Barriers in Building Envelope Design

By Positive Energy staff

The Misplaced Emphasis in The Moisture Management Puzzle

For decades, the architecture and construction community has engaged in a persistent debate surrounding the role and necessity of vapor barriers in building envelope design. This discussion, while touching on critical aspects of moisture control, has often been characterized by an overemphasis on the ability of specific materials to resist vapor diffusion, sometimes to the detriment of addressing more significant moisture transport mechanisms. Within the building science community, however, the principles governing moisture movement are largely considered settled science. It is well-established that air leakage, rather than vapor diffusion, is the predominant pathway for moisture transport through most wall assemblies.[1]

We’d like to put forth a compelling case for a fundamental shift in focus within the design and construction industries, from an often-misplaced obsession with vapor barriers, to a prioritized emphasis on achieving comprehensive air tightness. This is not a new idea and unfortunately not the only time it will have to be re-asserted. But by examining the historical context, the fundamental mechanisms of moisture transport, the distinct roles of air and vapor control layers, and the extensive benefits of air tightness, this blog post will demonstrate why a continuous air barrier system is a much more appropriate system of focus for creating durable, energy-efficient, and healthy buildings. We will also clearly delineate the necessary caveats where specific vapor diffusion control strategies remain essential, as in extreme climate zones or when dealing with reservoir claddings like stucco, brick, etc.

Historical Context and the Evolution of "Vapor Barrier Science"

The concept and application of vapor barriers in construction have undergone a significant evolution, shaped by early research, practical experience, and an advancing understanding of building physics. Historically, vapor barriers were largely a cold climate artifact, introduced with the primary intention of preventing moisture from indoor sources from migrating into wall cavities and condensing on cold exterior components during winter.[9] This initial focus was driven by observations of condensation-related damage in insulated wood-frame buildings in northern climates. This dynamic has been true of a number of early building science lessons and, while the research and literature has advanced, the public understanding of the current state of the literature requires repeated emphasis in order to properly affect practices in design and in the field.

To this very day, there is still considerable confusion between controlling vapor diffusion and controlling airflow. Much of that confusion lies in a misunderstanding of the principles of moisture transportation. Early building science informed attempts to manage moisture often involved using materials like sheet polyethylene, which, while an effective vapor retarder, was also tasked with acting as an air barrier, leading to the term "air-vapor barrier".[11] This dual-function approach, notably employed in programs like Canada's R-2000, aimed to create a sealed interior plane. However, achieving effective air tightness with polyethylene sheets proved daunting in practice. It required meticulous, painstaking effort to seal all laps and penetrations, often using acoustical sealants that were messy and difficult to work with.[11] This method was not great for typical production building speeds and its long-term robustness was questionable, as the thin plastic sheets were susceptible to damage during construction and over the building's service life.[11] This interior "air-vapor barrier" approach was also inherently climate-sensitive; in air-conditioned buildings, it placed a vapor-impermeable layer on the wrong side of the assembly during cooling seasons, potentially trapping moisture.[11]

Throughout the post-war years, practitioners were often taught, incorrectly, that interior vapor barriers were universally necessary in cold climates to protect assemblies, leading to the widespread adoption of kraft-faced and foil-faced batt insulation.[11] These facings, however, were inherently discontinuous and proved largely ineffective in preventing moisture problems, primarily because the dominant transport mechanism – air leakage carrying vapor – was not adequately addressed.[11]

As building science matured, a more nuanced understanding emerged. It became clear that vapor diffusion, the slow movement of water molecules through materials, was often a minor contributor to moisture accumulation compared to the substantial quantities of moisture that could be transported by air leaking through gaps and cracks in the building envelope.[3] This realization led to a refinement in terminology, with "vapor retarder" becoming the preferred term over "vapor barrier," acknowledging that most materials slow down diffusion rather than completely stopping it.[13] The term "vapor barrier" is now generally reserved for Class I vapor retarders, which are highly impermeable.[9]

Our understanding of vapor retarders today, and whether or not they are appropriate in a given building’s assemblies, involves a sophisticated, climate-specific approach. This is a significant departure from the initial, often misapplied, concept of a universal interior vapor barrier or even the notion of having a vapor barrier in the assembly at all. This evolution itself highlights that the early fixation on impermeable interior barriers was based on an incomplete understanding of moisture dynamics. Modern building codes, such as the International Residential Code (IRC) and International Building Code (IBC), now reflect this more mature understanding by mandating vapor retarders based on climate zone, often not requiring them at all in warmer climates, or allowing for more permeable options when certain conditions like exterior continuous insulation are met.[16] While codes aren’t perfect, the codification of climate-dependent strategies is still important because it is a clear indicator of the general consensus within the building science community.

Understanding Moisture Transport Mechanisms in Wall Assemblies

To effectively manage moisture in building envelopes, it is essential to understand the primary ways in which water, in its various phases, can move into and through wall assemblies. Building science identifies four principal mechanisms of moisture transport [5]:

Bulk Water Intrusion: This refers to the movement of liquid water—primarily from rain, snowmelt, or groundwater—through openings, cracks, or defects in the building envelope.[5] Examples include leaks at roof-wall intersections, poorly sealed window and door penetrations, or inadequate foundation drainage. Bulk water has the potential to introduce the largest quantities of moisture in the shortest time and is often the most damaging mechanism, leading to rapid saturation of materials, structural decay, and mold growth.5 Controlling bulk water through proper design of drainage planes, flashing, and water-shedding surfaces is the first line of defense in any moisture management strategy.[23]

Capillary Action: Capillarity is the ability of liquid water to be drawn into and move through the fine pores of materials, even against the force of gravity.[5] This "wicking" effect is common in porous materials like concrete, masonry, wood, and soil. Examples include moisture rising from damp ground into a concrete foundation wall or water being drawn into the end grain of wood siding.[13] While often less dramatic than bulk leaks, capillary action can lead to persistent dampness and significant hidden damage over time if capillary breaks (non-porous materials or air gaps) are not incorporated into the assembly.[13]

Air-Transported Moisture: Air can carry significant amounts of water in vapor form. When air moves through unintended openings in the building envelope (air leakage), it transports this moisture with it.[5] If warm, moist air leaks into a cooler part of the wall assembly, or contacts a surface below its dew point temperature, the water vapor can condense into liquid water.[12] This mechanism is driven by air pressure differences across the envelope, caused by wind, stack effect, or mechanical ventilation imbalances.[12]

Vapor Diffusion: This is the movement of water vapor at a molecular level through a material, driven by a difference in vapor pressure (concentration) or temperature.[5] Water vapor naturally moves from an area of higher concentration to an area of lower concentration, and from warmer to colder regions. The rate of diffusion depends on the vapor pressure gradient and the permeability of the material to water vapor.[13]

Of these four mechanisms, air-transported moisture is quantitatively the most significant pathway for water vapor entry into typical building cavities, far exceeding the amount transported by vapor diffusion alone. Numerous sources confirm that air leakage can transport 50 to 100 times more water vapor than diffusion through the same area of building material over the same period.[1] For instance, one study illustrates that while about 0.3 liters (1/3 quart) of water might diffuse through an intact 4×8-foot sheet of gypsum board during a heating season, a mere 1-square-inch hole in that same sheet could allow approximately 28.4 to 30 quarts of water to be carried into the wall by air leakage under typical pressure differences.[6] Renowned building scientist Joe Lstiburek similarly quantifies this difference, stating that moisture transport via air leaks is typically two orders of magnitude (a factor of 100) greater than through diffusion, even through a compromised vapor retarder.[7]

This disproportionate impact of air leakage is a fundamental concept that underpins the argument for prioritizing air tightness. Even if a "perfect" vapor retarder is installed to address diffusion, its overall effectiveness in controlling moisture will be severely compromised if pathways for air leakage remain. The persistent debate or overemphasis on vapor barriers within some segments of the construction industry often appears to overlook or insufficiently appreciate this crucial quantitative distinction—a distinction that has been well-established in building science for many years.[3] An effective moisture control strategy must, therefore, primarily focus on eliminating or drastically reducing air leakage.

Defining the Layers: Air Barriers vs. Vapor Retarders

A clear understanding of the distinct functions, materials, and performance metrics of air barriers and vapor retarders is crucial to dispel confusion and correctly prioritize moisture control strategies. While both contribute to managing the building envelope, they address different physical phenomena and moisture transport mechanisms.

Air Barriers:

The primary function of an air barrier system is to control the unintended movement of air into and out of a building and through its assemblies.[1] By controlling airflow, an air barrier inherently helps to manage air-transported moisture, which, as established, is a dominant vector for moisture problems.[1] An effective air barrier must be continuous over the entire building envelope, encompassing walls, roofs, and foundations, and meticulously sealed at all joints, penetrations (windows, doors, pipes, wiring), and transitions between different building components.[1]

Typical materials used for air barriers include specially designed membranes (house wraps), sheathing materials (like plywood or OSB with sealed joints), fluid-applied membranes, spray foam insulation (specifically closed-cell, when applied continuously), and even meticulously detailed gypsum board (though this approach has limitations).[2]

The performance of an air barrier material is quantified by its air permeance, typically measured in liters per second per square meter at a pressure differential of 75 Pascals (L/(s⋅m2) @ 75 Pa). A common benchmark for an air barrier material is an air permeance not greater than 0.02L/(s⋅m2) @ 75 Pa, as per ASTM E2178.[1] Whole building air tightness is often measured in air changes per hour at 50 Pascals (ACH50) using a blower door test.[28]

Vapor Retarders:

The primary function of a vapor retarder is to reduce the rate at which water vapor moves through a material via diffusion.[1] It does not, by its primary definition, control airflow. Again, the term "vapor retarder" is more accurate than the older term "vapor barrier" because most materials only slow down the process of diffusion rather than stopping it completely.[3] The term "vapor barrier" is often colloquially used to refer to Class I vapor retarders, which are very impermeable.[9]

The performance of a vapor retarder is measured by its water vapor permeance, commonly expressed in "perms." Materials are classified by their perm rating according to standards like ASTM E96:

Class I Vapor Retarder: ≤0.1 perm (vapor impermeable). Examples include polyethylene sheeting, non-perforated aluminum foil, glass, and sheet metal.1

Class II Vapor Retarder: > 0.1 perm to ≤1.0 perm (vapor semi-impermeable). Examples include kraft-faced fiberglass batt insulation, unfaced expanded or extruded polystyrene, some plywoods, and bitumen-coated paper.1

Class III Vapor Retarder: > 1.0 perm to ≤10 perms (vapor semi-permeable). Examples include gypsum board, latex or enamel paint (some paints), unfaced fiberglass insulation, cellulose insulation, and many house wraps.1 Materials with a perm rating greater than 10 are generally considered vapor permeable.2 The placement of vapor retarders is highly dependent on climate and the specific wall assembly design, generally positioned on the warm-in-winter side in cold climates to control outward diffusion, or sometimes on the exterior in very hot-humid climates if used, though often omitted in such climates to promote inward drying.4

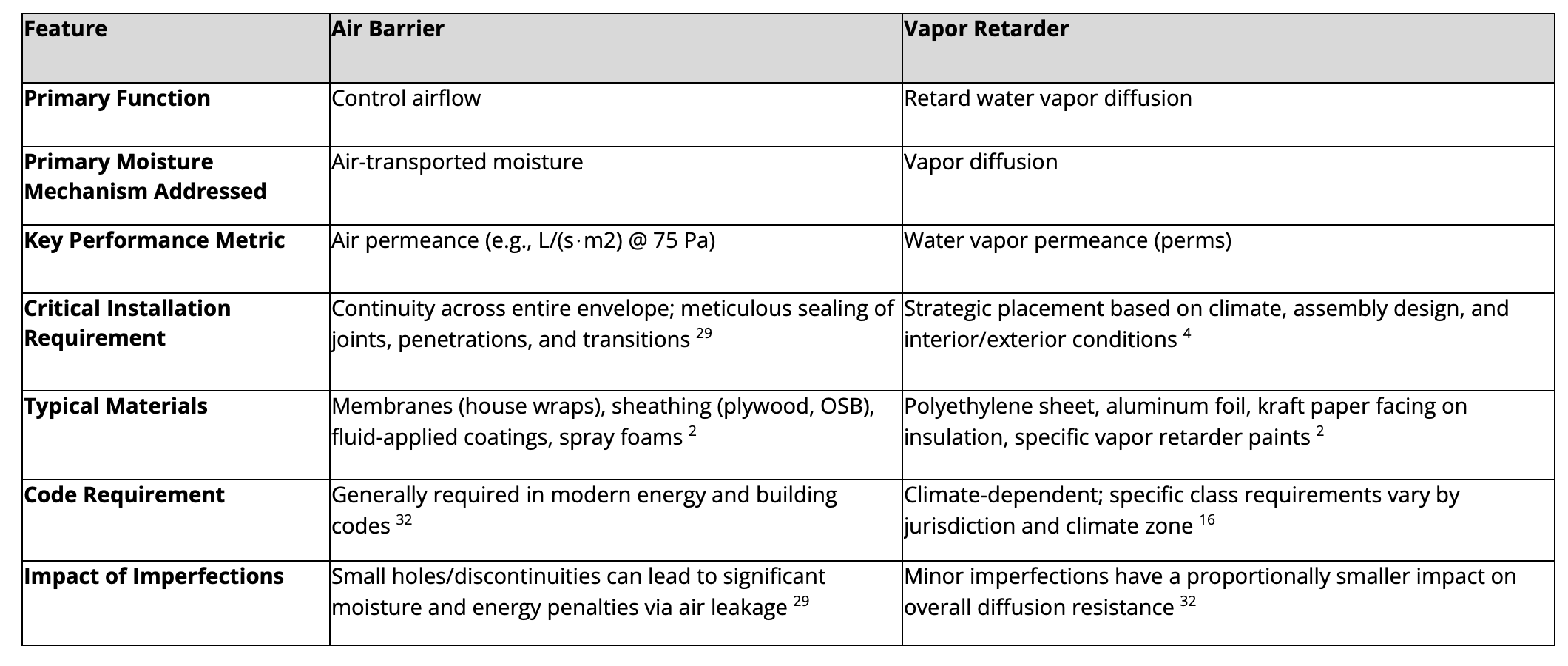

Table 1: Air Barrier vs. Vapor Retarder – A Functional Comparison

A critical source of ongoing confusion is the terminology itself. The term "vapor barrier," with its definitive "barrier" connotation, implies a more absolute and critical role in stopping all vapor movement than the more accurate term "vapor retarder," which reflects the function of managing diffusion rates.[13] This linguistic legacy subtly reinforces the notion that achieving a near-zero perm rating is a primary goal, overshadowing the more pressing need to stop air movement, which carries far more moisture.

The fact that some materials can function as both an air barrier and a vapor retarder (e.g., a meticulously sealed polyethylene sheet or continuous closed-cell spray foam) further blurs the functional distinctions in practice.[11] This can lead to the erroneous assumption that specifying a material for its vapor retarding properties automatically ensures adequate air barrier performance, or vice versa. However, the level of detailing and continuity required for an effective air barrier system is far more rigorous and unforgiving than what might be considered adequate for a vapor retarder whose primary role is to manage diffusion across its surface area.[29] A 10% discontinuity in a vapor retarder might mean it's 90% effective at retarding diffusion, but a 10% discontinuity in an air barrier system can lead to catastrophic failures in moisture and energy control.[32]

It is imperative for the design and construction industry to clearly separate the specification and performance targets for air control from those for vapor control. While integrated products and materials exist, the distinct functional requirements and, most importantly, the detailing for continuity of the air control layer, must be independently understood, specified, and meticulously executed to achieve desired building performance. Simply calling for a "vapor barrier" and hoping it also serves as an adequate air barrier is an approach fraught with risk.

The Primacy of Air Tightness: A Holistic Approach to Building Performance

Given that air leakage is overwhelmingly the dominant mechanism for moisture transport into and through building assemblies [1], the establishment of a continuous and robust air barrier system emerges as the single most critical strategy for effective moisture control. As building scientist Joseph Lstiburek succinctly states, "air barriers are a good idea everywhere, vapor barriers are not".[4] An effective air barrier minimizes the potential for condensation within the building envelope by preventing warm, moist air from reaching cold condensing surfaces.[12]

However, the importance of air tightness extends far beyond just moisture management. Achieving a high level of air tightness offers a multitude of interconnected benefits that contribute to overall building performance, occupant well-being, and long-term durability:

Energy Efficiency: This is perhaps the most widely recognized benefit. By minimizing uncontrolled air exchange (infiltration of outside air and exfiltration of conditioned inside air), air barriers significantly reduce heating and cooling loads. This translates directly to lower energy consumption, with potential reductions ranging from 10% to 40% in general buildings [29] and around 15% in homes designed to Zero Net Energy (ZNE) standards.31 Consequently, operational costs are lowered as HVAC systems do not have to work as hard to maintain desired indoor temperatures.[28]

Improved Comfort: Airtight buildings provide a more comfortable indoor environment by eliminating drafts and cold spots often associated with leaky envelopes.[31] This leads to more consistent and stable indoor temperatures throughout the conditioned space.

Enhanced Indoor Air Quality (IAQ): A continuous air barrier plays a crucial role in protecting IAQ by controlling the entry of outdoor pollutants such as dust, pollen, smoke, and soil gases like radon (which is primarily transported by air, not diffusion[7]).[29] Research indicates that airtight homes can reduce indoor concentrations of harmful PM2.5 particles by approximately 70% compared to conventional, leakier homes.[31] Furthermore, air tightness enables mechanical ventilation systems to operate much more effectively and predictably. Instead of relying on uncontrolled and often polluted air leakage paths, ventilation systems in tight buildings can provide the correct amount of fresh, filtered air from a known source, precisely managing indoor humidity and diluting internally generated pollutants.[31]

Building Durability: By significantly reducing the amount of moisture entering and moving through building assemblies via air leakage, air barriers mitigate the risk of moisture-related damage to building components. This includes preventing rot in wood framing, corrosion of metal components, and degradation of insulation materials, thereby extending the structure's lifespan and preventing premature failure of components.[28]

Acoustic Control: Well-sealed building envelopes can also contribute to improved sound isolation, reducing the transmission of exterior noise.[29]

The realization of these benefits hinges on one critical factor: the continuity and quality of workmanship of the air barrier system. Unlike vapor retarders, where minor imperfections might lead to a proportional decrease in diffusion resistance, the performance of an air barrier is fundamentally compromised by discontinuities.[32] As stated in one industry report, "The success of an air barrier system is highly dependent on skilled installation and adherence to detailed specifications. Because it is a barrier, any failure point can compromise the entire performance".[29] Many of you likely recognize the common failure points for air barriers, such as joints between materials, transitions between different assemblies (e.g., wall-to-roof, wall-to-foundation), and penetrations for windows, doors, pipes, and wiring.[29] Meticulous sealing of these areas using appropriate tapes, sealants, and gaskets is paramount, as is testing your results.[13] Achieving this level of continuity requires careful planning, coordination among trades, and a commitment to quality construction practices.[30]

The multiple, significant co-benefits derived from achieving superior air tightness—spanning energy savings, enhanced IAQ, improved durability, and greater occupant comfort—make it a far more impactful and cost-effective strategy to prioritize in building design and construction than a narrow focus on controlling vapor diffusion. Investing in a high-quality, continuous air barrier system yields substantial returns across a wide spectrum of building performance metrics. In contrast, an overemphasis on a specific class of vapor retarder primarily targets vapor diffusion, which is often a secondary moisture transport mechanism. When viewed through the broader lens of holistic building performance and lifecycle costs, the return on investment for achieving superior air tightness is demonstrably higher, making the historical "obsession" with vapor barriers appear even more disproportionate.

Interestingly, the very act of meticulously creating a continuous air barrier can often incidentally improve control over vapor diffusion, even if the primary air barrier material itself is vapor permeable (like many house wraps). Many pathways for air leakage, such as gaps at joints or around penetrations, also represent potential pathways for vapor diffusion if a vapor pressure differential exists across them. By diligently sealing these openings to achieve air control [29], one inherently reduces the surface area available for diffusion at these critical junctures. While the primary air barrier material might be designed to allow vapor to pass through it, the act of sealing its edges and integrating it continuously into the building envelope makes the overall assembly more resistant to all forms of gaseous transport through those specific, sealed leakage points. This implies that a dedicated focus on achieving comprehensive air tightness can indirectly bolster vapor control, whereas focusing solely on the perm rating of a vapor retarder does little to address the far more significant issue of air leakage.

This underscores the need for a shift in industry quality control and verification processes. While whole-building air leakage testing (e.g., blower door tests) is becoming more common and is mandated by some codes 28, the broader mindset shift towards viewing and executing "airtightness as a system" rather than merely installing an "air barrier product" is still developing. The emphasis on "construction quality and workmanship" 29 is far more critical for the successful performance of an air barrier system than it is for a vapor retarder.

The Importance of Dedicated Dehumidification

A core principle of durable building design is maintaining a moisture balance where the rate of moisture removal from an assembly consistently exceeds the rate of moisture entry. If wetting outpaces drying, moisture accumulation occurs, leading to degradation of materials, structural damage, and potential health issues from mold growth. While the strategies discussed previously—prioritizing air tightness and strategically using vapor retarders—are crucial for minimizing wetting, actively promoting drying is equally important, particularly in challenging conditions like a hot/humid climate.

In many modern, airtight homes, and especially in humid climates or buildings with high internal moisture loads (e.g., from occupants, cooking, construction moisture, etc.), relying solely on passive drying mechanisms (like vapor diffusion through permeable materials) or the incidental dehumidification provided by standard air conditioning systems may not be sufficient to ensure net drying. Air conditioning systems are primarily designed for sensible cooling (temperature control) and may not operate long enough or at optimal conditions to adequately remove latent moisture (humidity), especially during shoulder seasons or under partial load conditions.

This is where dedicated dehumidification systems play a critical role. These systems are designed specifically to remove excess moisture from the indoor air, thereby lowering the indoor relative humidity (RH). By maintaining a lower indoor RH (ideally between 30-60%, or even below 50%), a greater vapor pressure differential is established between the moist building materials and the drier indoor air. This enhanced differential significantly increases the drying potential of the assemblies towards the interior.

Benefits of Dedicated Dehumidification:

Enhanced Drying Capacity: Actively reduces indoor humidity, creating a more favorable gradient for moisture to move out of damp materials. This is crucial for drying incidental wetting from leaks, construction moisture, or even inward vapor drives that might bypass other defenses.

Improved Indoor Air Quality (IAQ) and Health: By maintaining lower RH, dedicated dehumidifiers help prevent conditions conducive to mold growth, dust mites, and other biological contaminants, which thrive in damp environments.

Occupant Comfort: Lower humidity levels are generally perceived as more comfortable, especially in warm weather.

Protection of Building Materials and Furnishings: Prevents moisture damage to structural components, insulation, finishes, and contents.

Complements Airtight Construction and Mechanical Ventilation: In highly airtight homes, where natural air exchange is minimal, mechanical ventilation (often with Energy Recovery Ventilators - ERVs) is essential for fresh air. While ERVs can help manage some moisture from incoming ventilation air, they do not actively dehumidify the interior space. Supplemental dehumidification works in tandem with these systems to ensure comprehensive moisture control.

Dedicated dehumidification systems can be whole-house units integrated with the HVAC system or standalone units. Their importance has become increasingly recognized, especially in high-performance building standards. Ensuring that the building can reliably dry out any moisture it encounters is a cornerstone of long-term durability (not to mention ensuring indoor air quality), and dedicated dehumidification provides a powerful tool to achieve this goal.

Strategic Use of Vapor Retarders: Necessary Caveats and Considerations

While air tightness is paramount, vapor retarders remain a necessary component of moisture control strategies in specific situations. Their use, however, must be guided by building science principles, particularly the critical need to facilitate drying. A fundamental principle of durable building envelope design is that assemblies should be designed to dry if they become wet, whether from incidental moisture intrusion or construction moisture.9 This necessitates the avoidance of "double vapor barriers"—impermeable layers on both the interior and exterior sides of an assembly—which can trap moisture and prevent drying in either direction.9 The building science consensus encourages "drying mechanisms over wetting prevention mechanisms" wherever feasible.[9]

The appropriate strategy for vapor control is highly dependent on climate and the type of cladding used.

Climate-Specific Needs for Vapor Control:

Extreme Cold Climates (e.g., ASHRAE/IECC Climate Zones 6, 7, 8, and Marine 4 in some instances):

Concern: Significant outward vapor drive from the warm, humidified interior to the cold exterior during winter, risking condensation on or within the cold exterior sheathing or other components of the wall assembly.[20]

Strategy: Typically, building codes mandate a Class I (e.g., polyethylene sheet, ≤0.1 perm) or Class II (e.g., kraft-faced insulation, > 0.1 to ≤1.0 perm) vapor retarder on the interior (warm-in-winter) side of framed walls.[10]

Nuances: Building scientist Joseph Lstiburek suggests that polyethylene (Class I) should generally be reserved for very cold hygro-thermal regions.[40] The addition of sufficient continuous exterior insulation can keep the wall cavity's condensing surfaces (like sheathing) warm enough to prevent condensation, potentially reducing or eliminating the need for a highly impermeable interior vapor retarder.[39] The IRC, for example, allows the use of Class III vapor retarders (e.g., latex paint, > 1.0 to ≤10 perms) in these cold zones if specific R-values of continuous exterior insulation are installed, or in some cases, with vented claddings.[17]

Hot-Humid Climates (e.g., ASHRAE/IECC Climate Zones 1A, 2A, parts of 3A):

Concern: Predominant vapor drive is from the hot, humid exterior to the cooler, air-conditioned interior during much of the year.[20]

Strategy: Interior vapor barriers (Class I or II) should generally be avoided to allow the wall assembly to dry towards the interior.[20] Some even emphatically claim that an interior polyethylene vapor barrier should "NEVER be installed" in these conditions if an exterior air/vapor barrier is present.[41] If an air/vapor barrier is used on the exterior (which can be beneficial for controlling bulk water and the strong inward vapor drive from outside), the wall assembly must be able to dry inwards. Lstiburek advocates for vapor-open assemblies in these climates, potentially with a vapor-permeable air control layer on the interior if masonry is part of the assembly.[44]

Mixed-Humid Climates (e.g., ASHRAE/IECC Climate Zones 3A, 4A, 4C):

Concern: Significant bi-directional vapor drive—outward in winter, inward in summer—makes the placement of a fixed, impermeable vapor barrier problematic.[4] A vapor barrier on the "wrong" side for part of the year can trap moisture.

Strategies:

"Smart" Vapor Retarders: These materials, such as CertainTeed MemBrain or ProClima Intello, have variable vapor permeance. They become more resistant to vapor diffusion (low perm) in dry conditions (typically winter interior) and more permeable (high perm) in humid conditions (typically summer, or if the cavity becomes wet).[45] For example, MemBrain is rated at ≤1 perm (dry cup) and > 10 perms (wet cup) [46], while Intello can range from < 0.13-0.23 perms to > 13 perms.[47] This adaptability allows drying in whichever direction is favored by the prevailing conditions.

Vapor-Open Assemblies: Designing walls to be generally vapor permeable on both sides of the insulation, often incorporating exterior continuous insulation. The primary moisture defense relies on the air barrier and bulk water management (flashing, drainage plane).[34]

Class II or Class III vapor retarders may be appropriate, as they allow a greater degree of drying than Class I materials.

Reservoir Claddings (e.g., Stucco, Brick, Stone, some Fiber Cement):

These claddings present a unique and critical challenge that demands specific attention beyond general climate-based rules.

The Challenge: Reservoir claddings absorb and store significant amounts of rainwater.24 When solar radiation subsequently warms the wet cladding, this stored moisture can be driven inward as a powerful vapor drive ("solar-driven inward vapor drive").[4] This inward pressure can overwhelm wall cavities, leading to condensation on interior layers, particularly if an impermeable interior vapor barrier like polyethylene is present and the building is air-conditioned.[55] This is a major caveat where focusing solely on controlling wintertime outward vapor drive from occupants is insufficient and potentially harmful.

Control Strategies for Inward Drive with Reservoir Claddings:

Ventilated Rainscreen/Cavity: A well-ventilated air space behind the cladding is a critical defense.[56] This gap (e.g., minimum 3/8 inch for many claddings, up to 1 inch or more for brick [56]) decouples the wet cladding from the rest of the wall assembly. It allows the inwardly driven moisture vapor to be carried away by airflow before it can penetrate the wall's weather-resistive barrier (WRB) and sheathing. Effective ventilation requires clear openings (vents) at both the top and bottom of the wall section.[56]

Appropriate WRB/Sheathing Permeance: The selection of the WRB and sheathing behind the ventilated cavity is crucial. In some designs, a WRB or sheathing with lower vapor permeance (acting as an exterior vapor control layer) might be used to "throttle" or resist the inward vapor drive.[56] However, this must be carefully balanced with the need for outward drying capability, especially in colder climates, to avoid creating a double vapor barrier situation.

Avoid Interior Impermeable Layers: In climates with significant air conditioning use, a Class I interior vapor retarder (like polyethylene) is generally contraindicated when reservoir claddings are present.[9] Such an interior barrier traps the solar-driven inward moisture, leading to condensation and potential damage. Lstiburek pointedly noted that the interior polyethylene sheets in many Vancouver condos in the 1980s and 1990s prevented the inward drying of rain-wetted stucco during the summer, contributing to widespread moisture problems.[40]

Additional Strategies: Reducing the reservoir capacity of the cladding itself by using paints or additives can lessen the inward drive potential.[58] Lstiburek advises that for reservoir claddings, one must either ventilate the airspace very effectively or use an exterior vapor throttle (like a dimple sheet behind the cladding) to intercept the inward drive; the key is that the air gap effectively uncouples the cladding from the wall assembly.[59]

Table 2: Vapor Retarder Strategies – Key Caveats and Considerations

The caveats for vapor retarder use are not minor exceptions. They represent common and critical construction scenarios, such as buildings with brick or stucco exteriors, or those located in the diverse climates across North America. In these situations, a simplistic "vapor barrier on the warm side" rule, often learned as a fundamental, can fail dramatically and cause significant harm if not critically assessed against the actual moisture physics at play.[14] The historical borderline obsession with vapor barriers may, in part, stem from an oversimplification of these complex interactions. When reservoir claddings are introduced, for example, solar-driven inward vapor drive becomes a powerful force that can overwhelm an assembly designed only to resist wintertime outward diffusion from occupant activities.[55] If the "warm side" rule is still rigidly applied with an interior polyethylene sheet in an air-conditioned building with a brick exterior, it inadvertently creates a moisture trap.[55] This demonstrates that the simple rule is insufficient for many common building types and that the borderline obsession might be with an incomplete rule itself, rather than a deep understanding of the building science that sometimes invalidates or modifies it.

The development and market presence of "smart" vapor retarders are a direct technological response to the documented failures of fixed-permeance vapor barriers in mixed climates or complex assemblies involving bi-directional vapor flow.[45] Their existence and promotion for challenging situations like mixed climates or unvented roof assemblies underscore that the "settled science" of moisture control includes acknowledging these complexities and providing advanced tools to address them. If traditional polyethylene (Class I) or kraft-facing (Class II) worked perfectly in all situations, there would be little impetus for materials that actively change their permeance in response to ambient humidity.[46] This reinforces that "settled science" does not equate to "simple science" in all applications of vapor control.

Ultimately, effective vapor control is less about finding a single perfect barrier material and more about understanding and managing vapor flow dynamics and drying potential within the entire building assembly, specific to its climate, materials, and operational conditions. This requires a significant shift from a product-centric thinking (i.e., "which vapor barrier product should I use?") to a system-centric, performance-based thinking (i.e., "how will this entire assembly manage all forms of moisture, including vapor, and ensure it can dry if it gets wet?").

Moving Forward: Prioritizing Air Tightness in Design and Construction

To align construction practices with established building science, the architecture and construction community must consciously shift its focus towards prioritizing air tightness. This requires changes in design philosophy, specification practices, on-site execution, and industry education.

Recommendations for the Architecture and Construction Community:

Prioritize Air Barrier System Design from Concept: The air barrier system should not be an afterthought or a layer simply added to the drawings. It must be a primary design consideration from the earliest conceptual stages. Designers need to clearly define the location of the continuous air control layer(s) and ensure this continuity is meticulously planned across all building assemblies and critical interfaces (e.g., wall-to-roof, wall-to-foundation, around penetrations).[29]

Specify for Air Tightness Performance, Not Just Products: Specifications should move beyond merely naming an air barrier material. They should include measurable air tightness targets for the whole building (e.g., a specific ACH50 value) and potentially for assemblies or components. Crucially, specifications must mandate verification through quantitative testing, such as whole-building blower door tests.[28] This shifts the focus from simply installing a product to achieving a verifiable performance outcome. Consider using the Phius performance standard for high levels of quality assurance and quality control.

Invest in Education and Training: Continuous education for design professionals, project managers, and construction crews is essential. This training should cover current building science principles related to air leakage, moisture transport mechanisms, the appropriate and strategic use of vapor retarders, and importantly, how to correctly detail and install air barrier systems.[30] Efforts should be made to actively address and debunk persistent misconceptions surrounding vapor barriers and air barriers.[40]

Develop and Implement Robust Detailing for Continuity: The success of an air barrier system lies in its continuity. Architects and designers must develop robust, practical, and buildable details for all penetrations, joints, and transitions between different air barrier materials or building assemblies. These details are where systems most commonly fail.[29]

Shift Mindset from "Vapor Barrier" to "Vapor Management": The industry needs to internalize that vapor control is about managing diffusion rates appropriate to the specific climate and assembly, not just about stopping all vapor movement with an impermeable layer. This involves embracing strategies like vapor-open assemblies or the use of smart vapor retarders where these approaches enhance the overall drying potential and resilience of the building envelope.[9]

Critically Evaluate "Rules of Thumb" and Historical Practices: Long-standing practices and simplified rules regarding vapor barrier placement should be critically examined against current building science. Decisions must be based on climate-specific, assembly-specific hygrothermal analysis rather than outdated or overly generalized guidelines.

The Role of Building Codes and Standards:

Building codes and industry standards play a vital role in driving practice. Continued advocacy for and support of code advancements that emphasize verifiable air tightness performance are necessary. Codes should also provide clear, science-based, and nuanced guidance on vapor retarder selection and placement, moving away from potentially problematic or overly simplistic blanket requirements. The evolution of codes to include mandatory air barrier requirements and air leakage testing is a positive development.[32] Standards like ASHRAE 90.1, which already mandate continuous air barriers with specific maximum air leakage rates for materials, assemblies, and whole buildings, provide a robust framework that can be more broadly adopted and rigorously enforced.[35]

Achieving a genuine shift in industry focus towards air tightness requires more than just better products; it demands better processes. From the initial design integration and clarity of specifications to the crucial inter-trade coordination and robust quality assurance/quality control (QA/QC) measures on the construction site, air tightness is a systems challenge.[29] It is not about a single product's performance in isolation but about how multiple components and materials are meticulously assembled by various trades to form a continuous, unbroken plane of air control. Therefore, simply specifying an "air barrier material" is insufficient. The design must explicitly show how this material connects and remains continuous across the entire envelope; trades must be trained in the specific techniques required for its correct installation; and site inspections, coupled with diagnostic testing, must verify that the intended performance is achieved.

This process-oriented approach is inherently more demanding than the simpler, often less critical, task of specifying and installing a sheet of polyethylene as a "vapor barrier."

The historical lack of widespread, rigorous air barrier verification (though this is improving with more stringent code requirements for testing [32]) has arguably allowed suboptimal air sealing practices to persist. Without consistent measurement and accountability for air tightness performance, the perceived urgency to perfect it may remain lower than its actual importance warrants. If air tightness is not consistently tested and failures are not identified and rectified [28], then the often severe consequences of poor air barrier detailing (e.g., hidden moisture damage, high energy bills, poor IAQ) are less immediately visible than, for instance, a bulk water leak from a poorly flashed window. This lack of immediate, obvious feedback can foster complacency or lead to a continued underestimation of air leakage's multifaceted impact, thereby allowing the "vapor barrier obsession" to continue as a more visible, albeit often less critical, focal point of moisture control discussions.

Ultimately, shifting the industry's predominant focus from vapor barriers to air tightness is a cultural transformation as much as a technical one. It will require a concerted and sustained effort involving designers (who must prioritize and detail for air continuity), builders and contractors (who must ensure meticulous execution and implement effective QA/QC), code officials (who must understand and enforce air tightness standards more rigorously), and even manufacturers (who should provide clearer guidance on system integration rather than focusing solely on individual product features).

A Call for a Science-Based Shift in Focus

The evidence from decades of building science research and field experience is unequivocal: air tightness is the most critical factor in controlling moisture transport through building assemblies in the majority of construction scenarios. The quantity of moisture carried by air leakage far surpasses that transported by vapor diffusion.[1] This fundamental understanding necessitates a paradigm shift in the architecture and construction community—a move away from an often disproportionate and historically rooted fixation on vapor barriers towards the primacy of designing and constructing robust, continuous air barrier systems.

This is not to say that vapor retarders have no role. They are indeed necessary tools, but their application must be strategic, nuanced, and firmly grounded in current building science. The "settled science" provides clear, climate-specific and assembly-specific guidance for their appropriate use, particularly in extreme cold climates and when dealing with the complexities of reservoir claddings and solar-driven inward vapor drive.[14] This modern understanding moves far beyond outdated, overly simplistic blanket rules that can, in many common situations, lead to moisture-related building failures by trapping moisture or impeding necessary drying.

Adopting a holistic, science-informed approach that prioritizes a continuous air barrier system, coupled with intelligent and context-appropriate vapor management strategies, offers profound benefits. Such an approach leads to buildings that are significantly more durable, energy-efficient, and provide healthier indoor environments for their occupants.[28] This shift not only reduces the risk of costly moisture-related failures and repairs but also improves occupant comfort and optimizes the allocation of resources in both design and construction phases.

The near obsession with vapor barriers is not merely an academic debate; it has tangible real-world consequences, contributing to building failures, energy waste, and compromised occupant health when it distracts from the more pressing need for air tightness.[28] Therefore, the advocated shift in focus is not just a technical correction but a matter of professional responsibility for those involved in creating the built environment.

It is time for the architecture and construction community to collectively move beyond the prolonged and often misdirected preoccupation with vapor barriers. Instead, the industry must embrace the well-established primacy of air tightness as the cornerstone of effective moisture control and overall building performance. Successfully making this transition will not only prevent common building problems but will also enhance the reputation and value proposition of the AEC industry by consistently delivering buildings that perform better, last longer, and truly align with the robust body of knowledge developed by the building science community. This alignment is crucial for creating a more sustainable, resilient, and healthy built future.

Works cited

Air Barrier vs Vapor Barrier: What are The Differences, accessed May 12, 2025, https://barricadebp.com/news/air-barriers-vs-vapor-barriers

Air Barrier vs Vapor Barrier- What You NEED to Know - Healthy Building Science, accessed May 12, 2025, https://healthybuildingscience.com/2024/02/01/air-barrier-vs-vapor-barrier-what-you-need-to-know/

Vapor barrier - Wikipedia, accessed May 12, 2025, https://en.wikipedia.org/wiki/Vapor_barrier

buildingscience.com, accessed May 12, 2025, https://buildingscience.com/sites/default/files/migrate/pdf/RR-0004_Air_Barrier_Vapor_Barrier.pdf

ENERGY SERIES: What about Moisture? | VCE Publications ..., accessed May 12, 2025, https://www.pubs.ext.vt.edu/2908/2908-9020/2908-9020.html

Understanding Moisture Flow | CertainTeed, accessed May 12, 2025, https://www.certainteed.com/inspiration/case-studies/understanding-moisture-flow

Air Barrier or Vapor Barrier? - Building Science Podcast ..., accessed May 12, 2025, https://www.greenbuildingadvisor.com/article/air-barrier-or-vapor-barrier-building-science-podcast

Controlling condensation from air leakage and vapour diffusion ..., accessed May 12, 2025, https://www.constructioncanada.net/controlling-condensation-from-air-leakage-and-vapour-diffusion/

BSD-106: Understanding Vapor Barriers | buildingscience.com, accessed May 12, 2025, https://buildingscience.com/documents/digests/bsd-106-understanding-vapor-barriers

Understanding Vapor Barriers - VaproShield, accessed May 12, 2025, https://vaproshield.com/images/stories/pdf/joe%20lstiburek%20understanding%20vapor%20barriers%20ashrae%202004%2008.pdf

BSI-084: Forty Years of Air Barriers\*—The Evolution of the ..., accessed May 12, 2025, https://buildingscience.com/documents/insights/bsi-084-forty-years-of-air-barriers

Moisture Transfer through Walls, accessed May 12, 2025, https://web.ornl.gov/sci/buildings/conf-archive/1989%20B4%20papers/044.pdf

www.southface.org, accessed May 12, 2025, https://www.southface.org/wp-content/uploads/2019/08/N082-Building-Science-101.pdf

Vapor Barriers or Vapor Retarders - Department of Energy, accessed May 12, 2025, https://www.energy.gov/energysaver/vapor-barriers-or-vapor-retarders

Building Science Digest 106 Understanding Vapor Barriers - andrew.cmu.ed, accessed May 12, 2025, https://www.andrew.cmu.edu/course/48-400/pdfs/Understanding%20Vapor%20Barriers.pdf

Vapor Barrier Code Requirements: Crawl Space & Building… | Polyguard, accessed May 12, 2025, https://polyguard.com/blog/vapor-barrier-code-requirements

2021 International Building Code (IBC) - CHAPTER 14 EXTERIOR WALLS - 1404.3 Vapor retarders., accessed May 12, 2025, https://codes.iccsafe.org/s/IBC2021P1/chapter-14-exterior-walls/IBC2021P1-Ch14-Sec1404.3

2021 International Residential Code (IRC) - CHAPTER 7 WALL ..., accessed May 12, 2025, https://codes.iccsafe.org/s/IRC2021P3/chapter-7-wall-covering/IRC2021P3-Pt03-Ch07-SecR702.7

Moisture Control | Vapor Retarders, Residential, Installing - Insulation Institute, accessed May 12, 2025, https://insulationinstitute.org/im-a-building-or-facility-professional/residential/installation-guidance-2/moisture-management/vapor-retarders/

www.iccsafe.org, accessed May 12, 2025, https://www.iccsafe.org/wp-content/uploads/proclamations/TN06-Vapor-Retarders_pdf.pdf

i LABORATORY Moisture Control Handbook - UNT Digital Library, accessed May 12, 2025, https://digital.library.unt.edu/ark:/67531/metadc696747/m2/1/high_res_d/586594.pdf

Moisture Ingress in Building Envelope Materials: (II) Transport Mechanisms and Practical Mitigation Approaches - MDPI, accessed May 12, 2025, https://www.mdpi.com/2075-5309/15/5/762

buildingscience.com, accessed May 12, 2025, https://buildingscience.com/sites/default/files/migrate/pdf/BSD-106_Understanding%20Vapor%20Barriers_2013.pdf

Vapor Barriers and Wall Design - Building Science, accessed May 12, 2025, https://buildingscience.com/sites/default/files/migrate/pdf/RR-0410_Vapor_Barriers_Wall_Design.pdf

Building Science Digest 106 Understanding Vapor Barriers - revfoam insulation, accessed May 12, 2025, https://revfoam.com/wp-content/uploads/2015/01/BSD-106_Understanding-Vapor-Barriers_2013.pdf

Controlling Moisture Movement in Buildings - W. R. Meadows, accessed May 12, 2025, https://www.wrmeadows.com/data/cat-mm03.pdf

Moisture accumulation in walls due to air leakage, accessed May 12, 2025, https://publications-cnrc.canada.ca/eng/view/ft/?id=aebbca87-8deb-4f03-9ca9-ba27712f9297

The Role of Air Barriers in Modern Construction - Intertek, accessed May 12, 2025, https://www.intertek.com/blog/2025/02-25-air-barriers-in-modern-construction/

The impact of air barriers in meeting new energy codes - Salas O'Brien, accessed May 12, 2025, https://salasobrien.com/news/energy-code-air-barrier/

Common Air Barrier Failures and How to Avoid Them, accessed May 12, 2025, https://475.supply/blogs/design-construction-resources/common-air-barrier-failures-and-how-to-avoid-them

Benefits of Superior Airtightness - SVACH, accessed May 12, 2025, https://svach.lbl.gov/benefits-superior-airtightness/

The Last Word (We Hope) on Vapor Barriers | JLC Online, accessed May 12, 2025, https://www.jlconline.com/how-to/insulation/the-last-word-we-hope-on-vapor-barriers_o

Air Barrier vs Vapor Barrier: Key Differences, Benefits - METALCON 2025, accessed May 12, 2025, https://metalcon.com/blog/air-barrier-vs-vapor-barrier-how-do-they-differ/

BSC Information Sheet 311 Vapor Open Assemblies - Building Science, accessed May 12, 2025, https://buildingscience.com/sites/default/files/migrate/pdf/BSCInfo_311_Vapor_Open_Assemblies.pdf

ANSI/ASHRAE/IES Standard 90.1-2019: Envelope - Oregon.gov, accessed May 12, 2025, https://www.oregon.gov/bcd/codes-stand/Documents/90.1-2019-Envelope-training.pdf

Tight Air-Sealed Homes | Building Science Education, accessed May 12, 2025, https://bsesc.energy.gov/energy-basics/tight-air-sealed-homes

BSC Information Sheet 311 - Vapor Open Assemblies, accessed May 12, 2025, https://www1.eere.energy.gov/buildings/publications/pdfs/building_america/vapor_open_assemblies.pdf

PA-0401: Built Wrong from the Start | buildingscience.com, accessed May 12, 2025, https://buildingscience.com/documents/published-articles/pa-built-wrong-from-start/view

Is vapour barrier a bad idea for a house that has cold winters and hot humid summers?, accessed May 12, 2025, https://www.reddit.com/r/Homebuilding/comments/1gr4l4a/is_vapour_barrier_a_bad_idea_for_a_house_that_has/

Vapor Barrier Confusion : r/buildingscience - Reddit, accessed May 12, 2025, https://www.reddit.com/r/buildingscience/comments/1jhgu31/vapor_barrier_confusion/

www.carlisleccw.com, accessed May 12, 2025, https://www.carlisleccw.com/download.aspx?id=797&fileID=37

Vapor Barrier and humidity : r/buildingscience - Reddit, accessed May 12, 2025, https://www.reddit.com/r/buildingscience/comments/1784d5b/vapor_barrier_and_humidity/

The Truth About Vapor Permeability in High Humidity Environments - DuPont, accessed May 12, 2025, https://www.dupont.com/content/dam/dupont/amer/us/en/performance-building-solutions/public/documents/en/bsb-the-truth-about-vapor-permeability-43-d100849-enna.pdf

Building America Webinar: Stump the Building Science Chump — Joe Lstiburek (Text Version) | Department of Energy, accessed May 12, 2025, https://www.energy.gov/eere/buildings/building-america-webinar-stump-building-science-chump-joe-lstiburek-text-version

Vapour Barrier or Vapour Retarder? (Exposing important myths and ..., accessed May 12, 2025, https://litebox.ca/vapour-barrier-or-vapour-retarder-exposing-important-myths-and-misconceptions/

MemBrain™ | CertainTeed, accessed May 12, 2025, https://www.certainteed.com/products/building-insulation-products/membrain

Smart Vapor Retarders for Walls and Roofs - Fine Homebuilding, accessed May 12, 2025, https://www.finehomebuilding.com/project-guides/insulation/smart-vapor-retarders-for-walls-and-roofs

Understanding Air Barriers and Vapor Retarders: Why and Where to Place Them - Hypo Air, accessed May 12, 2025, https://hypoair.com/blogs/news/understanding-air-barriers-and-vapor-retarders-why-and-where-to-place-them

Reinforced all-round hydrosafe® high-performance vapour check - INTELLO X PLUS | pro clima international, accessed May 12, 2025, https://proclima.com/products/internal-sealing/intello-x-plus/technical-specs

Technical specs - INTELLO | pro clima international, accessed May 12, 2025, https://proclima.com/products/internal-sealing/intello/technical-specs

MemBrain™, The SMART Vapor Retarder - IDI: Insulation, accessed May 12, 2025, https://www.idi-insulation.com/wp-content/uploads/2020/06/MemBrain-SMART-Vapor-Retarder.pdf

Cetainteed MemBrain Vapor Retarder (All Sizes) - Shop Online - Insulation4US, accessed May 12, 2025, https://insulation4us.com/products/cetainteed-membrain-vapor-retarder-all-sizes

Pros and cons of a "vapor open" exterior wall assembly with/without rigid sheathing?, accessed May 12, 2025, https://www.greenbuildingadvisor.com/question/pros-cons-of-a-vapor-open-exterior-wall-assembly-with-without-rigid-sheathing

Joe Lstiburek Discusses Basement Insulation and Vapor Retarders - GreenBuildingAdvisor, accessed May 12, 2025, https://www.greenbuildingadvisor.com/article/joe-lstiburek-discusses-basement-insulation-and-vapor-retarders

RR-0104: Solar Driven Moisture in Brick Veneer | buildingscience.com, accessed May 12, 2025, https://buildingscience.com/documents/reports/rr-0104-solar-driven-moisture-in-brick-veneer/view

www1.eere.energy.gov, accessed May 12, 2025, https://www1.eere.energy.gov/buildings/publications/pdfs/building_america/reservoir_cladding.pdf

Brick, Stucco, Housewrap and Building Paper, accessed May 12, 2025, https://buildingscience.com/sites/default/files/migrate/pdf/RR-0105_Brick_Stucco_Housewrap_Paper.pdf

BSI-091: Flow-Through Assemblies | buildingscience.com, accessed May 12, 2025, https://buildingscience.com/documents/building-science-insights-newsletters/bsi-091-flow-through-assemblies

How to Protect Stucco Buildings from Moisture | Dr. Joe Lstiburek - YouTube, accessed May 12, 2025, https://www.youtube.com/watch?v=fBj4l3pzmss

Vapor Barrier Myths and Facts - Basement Waterproofing by Al, accessed May 12, 2025, https://basementwaterproofingbyal.com/waterproofing/vapor-barrier-myths-facts/