A Building Science Dive into the Hill Country Wine Cave

by Positive Energy staff

Clayton Korte's Vision and the Subterranean Setting

The Hill Country Wine Cave, a distinctive architectural endeavor by Clayton Korte Architects, is intricately integrated into the natural landscape of the Texas Hill Country. This private subterranean structure is carved into the north face of a solid limestone hillside, designed to nearly vanish into its surroundings.[1] Completed in 2020, the 1,405 square meter facility encompasses a tasting lounge, a bar, a restroom, and a dedicated wine cellar capable of storing approximately 4,000 bottles.[3]

The project originated from an existing excavated tunnel, measuring 18 feet tall and 70 feet deep.[4] Clayton Korte's design philosophy for the cave emphasized a "minimal intervention into the landscape".[2] The exterior entry court is discreetly camouflaged by heavy limestone boulders, collected directly from the excavation, and further obscured by lush native vegetation.[2] The mouth of the cave is capped with a board-formed concrete portal, specifically designed to weather naturally over time, allowing native moss and ivy to cling to its surface and further blend the structure with the irregular limestone hillside.[3]

Inside, the interior spaces present a sophisticated interplay of materials. White oak, both raw and ebonized, along with vertical-grain Douglas fir, panels the walls and dropped ceilings, providing a warm and tactile contrast. This refined interior is strategically juxtaposed with the exposed, rugged shotcrete-lined walls of the original cave, which are deliberately left visible in certain areas, including the bathroom.[4] Custom insulated and thermally broken steel and wood windows are integral to the design, offering visual connections to the exterior while also serving to separate the internal zones, such as the lounge from the chilled cellar.[5]

The Imperative of Building Science in Unique Environments

Building science is an interdisciplinary field that examines the physical behavior of buildings and their dynamic interaction with both the indoor and outdoor environments. Its application is fundamental to ensuring the long-term durability, energy efficiency, and occupant health of any structure. In the context of subterranean environments, this scientific discipline becomes particularly critical.

While subterranean structures offer inherent advantages, such as significant thermal stability due to the earth's buffering capacity, they also present a distinct set of complex challenges. The Hill Country Wine Cave exemplifies this dual nature. The earth's large heat capacity allows it to absorb and store thermal energy, contributing to naturally cooler subterranean temperatures that benefit wine preservation.[6] However, the existing excavated cave was explicitly noted as "neither water-tight nor necessarily designed for this intent".[8] This condition implies that while the passive thermal benefits are substantial, they are not sufficient on their own to create a precisely controlled, durable environment suitable for sensitive contents like wine. Significant intervention is required to manage potential moisture intrusion and to achieve the specific, consistent climate control necessary for wine aging. This interplay between leveraging natural advantages and addressing inherent environmental challenges underscores the indispensable role of a rigorous building science approach in such projects.

Positive Energy's Role: Elevating Performance Through MEP Engineering

Positive Energy served as the Mechanical Engineer for the Hill Country Wine Cave project.[3] Positive Energy is an MEP engineering firm specializing in high-end residential architecture, driven by a commitment to leveraging building science and human-centered design to engineer healthy, comfortable, and resilient spaces.[17] Our approach is characterized by a deep level of design resolution and a focus on solving complicated building science challenges.[18] One of the firm principasl and co-founder, Kristof Irwin, has a background combining 12 years as a custom builder with 19 years as a building science consultant and MEP engineer, preceded by 14 years as an engineer, research scientist, and high-energy physicist.[19] This diverse and interdisciplinary expertise positioned Positive Energy as critical integrators in the design process with a diverse perspective. Our involvement extended beyond merely selecting mechanical equipment; it encompassed a deep understanding of the underlying physics of heat, air, and moisture flow within and around the structure. This comprehensive understanding ensures that the project's ambitious performance goals are met within the challenging subterranean context, effectively bridging the architectural vision with the intricacies of building physics.

Thermal Performance and Moisture Control

Leveraging Earth's Natural Stability

The earth's subsurface offers a remarkable thermal buffer, maintaining relatively constant temperatures year-round at depths typically ranging from 20 to 30 feet below grade.[13] This inherent thermal stability significantly reduces the energy required to maintain optimal indoor conditions compared to structures exposed directly to fluctuating ambient temperatures above ground.[13] The Hill Country Wine Cave directly benefits from these "naturally colder subterranean temperatures," which act as a primary passive thermal control mechanism for the wine cellar.[4]

Research from institutions such as Lawrence Berkeley National Laboratory (LBNL) and the National Renewable Energy Laboratory (NREL) consistently highlights the ground's substantial heat capacity, enabling it to absorb and store thermal energy—whether heat or cold—for extended periods.[11] This fundamental principle is actively leveraged in advanced technologies like Underground Thermal Energy Storage (UTES) and Aquifer Thermal Energy Storage (ATES), which aim to reduce cooling loads and enhance grid resilience by utilizing the earth as a thermal battery.[12]

While the subterranean environment provides a substantial passive thermal advantage, achieving the precise and stable conditions required for wine preservation (typically 55-60°F or 12.7-15.5°C) necessitates active, high-efficiency mechanical systems to refine and consistently maintain the indoor climate.[6] This demonstrates that the natural conditions serve as an excellent baseline, significantly reducing the overall energy burden, but they are not sufficient in isolation for sensitive applications like wine storage. The design strategy aimed to "lower the temperature delta between the building envelope and cave" [8], a strategic passive design move that effectively reduces the operational load on the active mechanical systems, thereby enhancing their energy efficiency rather than eliminating the need for them entirely.

To further illustrate the inherent thermal advantages of subterranean construction, a comparison with typical above-grade environments is presented below:

The "Ship in a Bottle" Enclosure Strategy for Durability and Resilience

The architectural solution employed by Clayton Korte for the Hill Country Wine Cave involved inserting a "wooden module like a 'ship in a bottle'" into the existing excavated tunnel.[4] This module was meticulously designed, informed by a detailed 3D scan of the irregular cave interior.[4]

The primary function of this interior module is twofold: to create a "waterproof and human-scale" environment within the cave and to "avoid physical interaction with the cave wall".[4] This deliberate separation is crucial for protecting the conditioned interior from potential moisture intrusion and the inherent darkness of the cave. The interior walls, clad in wood, offer a warm aesthetic that contrasts with the exposed shotcrete-lined cave walls, which are strategically revealed in certain areas.[4] This design approach successfully maintains a "sense of subterranean occupation without the overwhelming environmental conditions that would make one seek to leave".[4]

Controlling Moisture: Preventing Water Entry and Accumulation

A significant challenge in the Hill Country Wine Cave project was the inherent moisture conditions of the existing cave, which was explicitly noted as "neither water-tight".[8] Concrete, even when applied as shotcrete, can exhibit "sweating" [21], and all underground structures are susceptible to various forms of moisture ingress, including rainwater, groundwater, air transport, and vapor diffusion.[22] Effective moisture management was therefore paramount to the project's success and long-term durability.

Building science principles, as advocated by organizations like Building Science Corporation (BSC), Phius, and RDH, guided the strategies for moisture control:

Source Control: The most effective approach to moisture management begins by preventing water from ever reaching the building assembly.[21] This involves meticulous site grading to divert rainwater away from the foundation perimeter and the installation of sub-grade perimeter footing drains to manage groundwater before it can accumulate against the foundation wall.[24]

Dampproofing: This crucial measure protects foundation materials from absorbing ground moisture through capillary action.[24] It is distinct from waterproofing, which attempts to create an impermeable barrier—a task often deemed unachievable in practice, as "even boats need pumps".[24] Dampproofing typically involves applying a tar or bituminous coating to the exterior of the concrete foundation wall.[24]

Control Layers: Durable wall assemblies rely on a combination of integrated control layers:

Water Resistive Barrier (WRB): This inner layer serves as the final line of defense against liquid water that might penetrate the outer layers of the assembly.[25]

Air Barrier: An essential component that stops heat and moisture movement driven by air transport.[22] Phius emphasizes that airtight construction is critical to prevent warm, moist air from leaking into wall cavities, where it can condense on colder surfaces and lead to mold growth.[26] For subterranean applications, an air barrier is typically required on the concrete wall, connecting seamlessly to the above-grade wall assembly.[27]

Vapor Retarder/Barrier: This layer controls the movement of water vapor through diffusion, preventing its accumulation within the building assembly.[22] Its precise placement within the wall assembly is determined by the specific climate and the direction of moisture drive.[22]

Drainage Plane/Cavity: The "ship in a bottle" design inherently creates a strategic cavity between the natural shotcrete-lined cave wall and the inserted interior wooden module. This intentional gap functions similarly to a rainscreen system [25], allowing any bulk water seeping from the irregular cave surface to drain downwards and away, and enabling water vapor to dry into this space. This approach is a robust and forgiving method for managing moisture, as it does not rely on a single, potentially fallible "waterproof" layer applied directly to the irregular cave surface. Instead, it creates a controlled environment where moisture is actively managed and directed away from the conditioned space, ensuring the long-term durability of the interior assembly.

Continuous Insulation: Phius principles underscore the importance of continuous insulation to interrupt thermal bridges.[26] In subterranean applications, this is particularly vital to keep interior surfaces warm, thereby preventing condensation that can occur when humid interior air comes into contact with cold wall surfaces.[26]

The following table provides a clear, actionable framework for designing durable subterranean wall assemblies, bridging theoretical building science principles with practical application:

Supplemental Systems: High-Efficiency MEP for Precision Environmental Control

Despite the significant thermal stability provided by the surrounding earth, supplemental cooling is essential to maintain the precise optimal atmosphere required for wine preservation. The wine cellar is targeted for a temperature range of 55-60°F (12.7-15.5°C), while the lounge area is maintained at a comfortable 76°F (24.4°C).[6] This precise control is critical for the long-term aging and quality of the 4,000-bottle collection.[4]

Positive Energy's mechanical design incorporated high-efficiency 20 SEER/10.4 HSPF heat pump equipment.[7] This selection reflects a commitment to energy performance and sustainability, ensuring that the active systems operate with minimal energy consumption. The overall design strategy aimed to "lower the temperature delta between the building envelope and cave".[8] This approach intelligently leverages the passive benefits of the subterranean environment to reduce the overall load on the mechanical systems, thereby enhancing their operational efficiency and reducing energy consumption.

Maintaining optimal conditions for wine storage presents a unique environmental control challenge, often referred to as a "Goldilocks" scenario: the environment must be neither too hot, nor too cold, nor too humid, nor too dry, and crucially, it must be free from harmful airborne contaminants. This necessitates highly precise and integrated MEP systems that can perform both cooling and dehumidification, often simultaneously, to meet the stringent requirements for wine preservation.[6] ASHRAE guidelines emphasize the importance of humidity control for material preservation, preventing issues such as wood shrinkage and mold growth, which are particularly relevant in a space with extensive timber finishes and sensitive contents.[29] This holistic environmental control goes far beyond the scope of typical comfort conditioning, demanding a sophisticated understanding of psychrometrics and building physics.

Cultivating Optimal Indoor Air Quality for Wine and Occupants

The Science of Wine Preservation: Critical Parameters (Temperature, Humidity, VOCs)

Beyond temperature, the quality of the indoor environment, particularly humidity and air composition, is paramount for wine preservation. Optimal humidity levels are crucial to prevent corks from drying out, which could lead to excessive oxygen ingress and spoilage of the wine, while also mitigating the risk of mold growth at excessively high humidity levels.[29]

A significant concern in wine cellars is the presence of Volatile Organic Compounds (VOCs). These chemical compounds can originate from various sources, including building materials, finishes, and even components of the wine bottles themselves, such as label glues.[30] VOCs are explicitly recognized as "harmful to wine" and can cause "bad odours," potentially tainting the wine's flavor and aroma.[30] This is exacerbated by the fact that corks are not completely airtight, allowing for "nano infiltration" of these airborne molecules into the bottle.[30] In specialized environments like wine caves, indoor air quality extends beyond considerations for human health and comfort to become a critical factor in product preservation. This necessitates careful material selection and potentially advanced air treatment strategies to protect sensitive contents from degradation.

Designing for Healthy Air: Advanced Ventilation and Filtration Strategies

Maintaining acceptable indoor air quality (IAQ) is crucial for both the long-term preservation of the wine and the health and comfort of human occupants. Recognized standards, such as ASHRAE Standards 62.1 and 62.2, provide comprehensive guidelines for ventilation system design and acceptable IAQ, outlining minimum ventilation rates and other measures to minimize adverse health effects.[31] These standards underscore that IAQ is a multifaceted concept, encompassing not only ventilation but also the performance of mechanical equipment, filtration systems, and environmental controls.[31]

While specific details regarding the Hill Country Wine Cave's ventilation and filtration systems are not extensively provided in the available information, the involvement of Positive Energy, a firm deeply committed to building science and human-centered design, strongly suggests a sophisticated and performance-driven approach.[17] For environments highly sensitive to VOCs, effective strategies typically include the rigorous selection of low-emission building materials and finishes, as well as the potential deployment of advanced filtration systems specifically designed to capture and remove VOCs from the air.[30]

Humidity control is an integral component of overall IAQ, directly influencing human respiratory health, preventing the proliferation of mold, and preserving hygroscopic materials like the extensive wood finishes present in the cave.[29] The optimal relative humidity for human occupancy is generally considered to be between 30% and 60%.[29] The precise management of these parameters is essential for both wine preservation and human comfort. Optimal IAQ in a wine cave represents a complex interplay of temperature, humidity, ventilation, and contaminant control. Each of these parameters influences the others, requiring a finely tuned and integrated mechanical system to meet the dual demands of sensitive product preservation and a comfortable, healthy human experience.

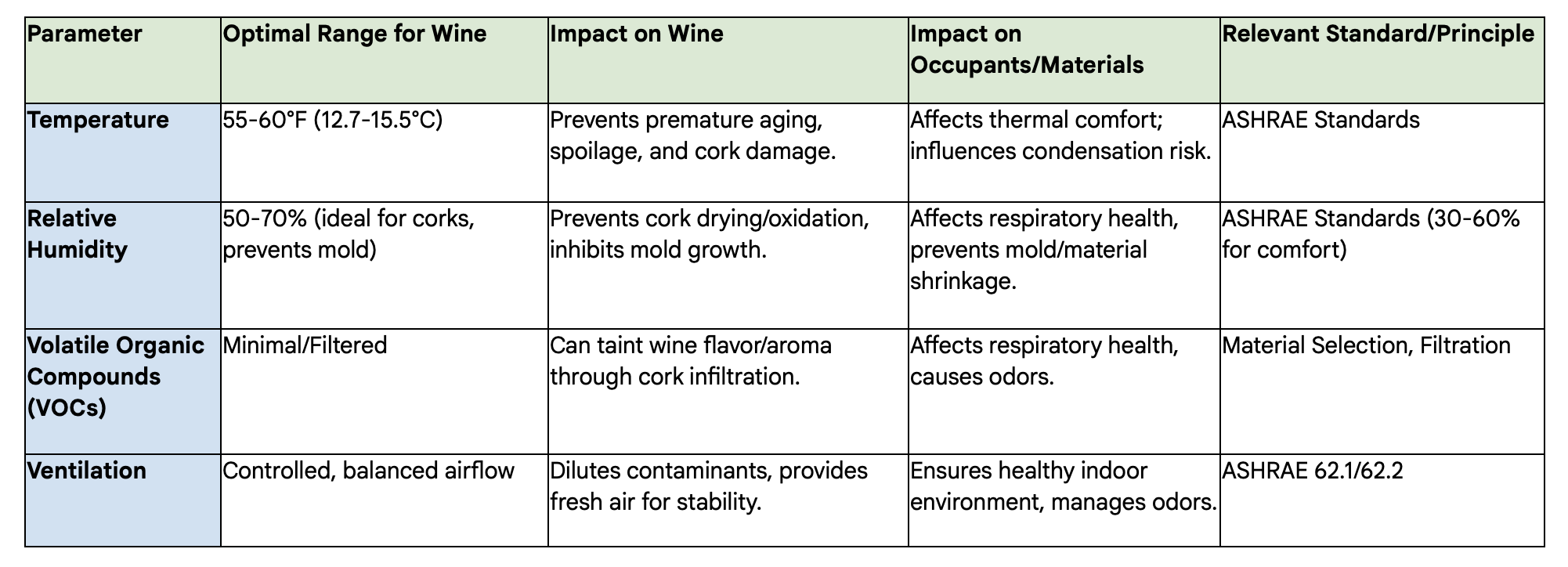

The following table summarizes the key environmental parameters that define optimal IAQ in a wine cellar, highlighting their dual importance for wine preservation and human comfort:

Integrated Design for Enduring Performance

Key Takeaways for Architects

The Hill Country Wine Cave stands as a compelling illustration of how ambitious architectural vision, when deeply integrated with rigorous building science principles and expert MEP engineering, can successfully transform a challenging natural environment into a high-performance, durable, and aesthetically rich space. For architects navigating increasingly complex projects, several key lessons emerge from this endeavor:

Embrace System Thinking: A building, particularly a subterranean one, functions as a complex, interconnected system. Its overall performance is not merely the sum of isolated components but rather a direct result of how all elements—the site, the building envelope, and the mechanical systems—interact. The "ship in a bottle" concept employed in the Wine Cave is a prime example of this systemic approach, creating a precisely controlled interior environment within a naturally variable, uncontrolled exterior. This strategy acknowledges that the built environment is a dynamic system, where changes in one part can profoundly affect others.

Moisture Management is Paramount: For subterranean structures, moisture control cannot rely on a single, infallible "waterproof" layer. Instead, it demands a multi-layered, comprehensive strategy that addresses bulk water intrusion, capillary action, air-transported moisture, and vapor diffusion. This involves strategic site drainage, effective dampproofing, robust air barriers, appropriately placed vapor retarders, and continuous insulation. Crucially, the deliberate creation of a drainage and ventilation gap—akin to a subterranean rainscreen—provides a forgiving and effective mechanism for managing incidental moisture and promoting drying, ensuring the long-term integrity of the interior assembly.

Leverage Passive, Refine Actively: Maximizing the inherent benefits of the site, such as the earth's significant thermal mass, can substantially reduce the energy load on mechanical systems. This passive conditioning provides a stable baseline. However, for applications requiring precise environmental control, such as wine preservation, high-efficiency active mechanical systems are indispensable. The optimal design integrates these passive and active strategies, allowing the natural environment to do the heavy lifting while sophisticated systems provide the necessary fine-tuning.

Indoor Air Quality Extends Beyond Comfort: In specialized environments, the considerations for indoor air quality (IAQ) must encompass not only human health and comfort but also the preservation of sensitive contents. This necessitates meticulous material selection to minimize off-gassing, robust ventilation strategies to dilute contaminants, and potentially advanced filtration systems to mitigate specific airborne pollutants like Volatile Organic Compounds (VOCs) that could compromise product integrity. The precise management of temperature, humidity, and air purity becomes a critical factor in the success of the space.

The success of the Hill Country Wine Cave demonstrates that integrating building science expertise, such as that provided by Positive Energy, from the earliest design stages is crucial. This proactive engagement allows project teams to anticipate and effectively mitigate complex environmental challenges inherent in unique projects, ultimately leading to superior performance, enhanced durability, and long-term value.

The Value of Expert MEP and Building Science Collaboration in High-Performance Design

The Hill Country Wine Cave stands as a powerful testament to the efficacy of collaborative design. The architectural vision of Clayton Korte was not only supported but profoundly enhanced by the specialized building science and MEP engineering expertise of Positive Energy. This partnership was instrumental in ensuring that the ambitious aesthetic and experiential goals of the project were achieved without compromising on critical performance metrics related to thermal stability, comprehensive moisture management, and optimal indoor air quality.

For architects navigating an increasingly complex built environment and facing growing demands for high-performance structures, engaging with specialized MEP and building science consultants is no longer a supplementary consideration but a fundamental component of delivering truly high-performance, durable, and healthy built environments. This project vividly exemplifies how such deep collaboration leads to innovative and resilient solutions that thoughtfully respect both natural conditions and human needs.

Works cited

Hill Country Wine Cave: Clayton Korte - Amazon.com, accessed May 28, 2025, https://www.amazon.com/Hill-Country-Wine-Cave-Clayton/dp/1964490006

Hill Country Wine Cave - Clayton Korte - Oscar Riera Ojeda Publishers, accessed May 28, 2025, https://www.oropublishers.com/products/hill-cohill-country-wine-cave-clayton-korte

Hill Country Wine Cave Clayton Korte - World-Architects, accessed May 28, 2025, https://www.world-architects.com/ro/clayton-korte-austin/project/hill-country-wine-cave

Clayton Korte embeds hidden wine cave into Texas hillside - Dezeen, accessed May 28, 2025, https://www.dezeen.com/2021/03/23/clayton-korte-hill-country-wine-cave/

Clayton Korte Creates Private Wine Cave Embedded Into Native Landscape Of Texas Hillside - World Architecture Community, accessed May 28, 2025, https://worldarchitecture.org/architecture-news/evcmg/clayton-korte-creates-private-wine-cave-embedded-into-native-landscape-of-texas-hillside

Hill Country Wine Cave / Clayton Korte - ArchDaily, accessed May 28, 2025, https://www.archdaily.com/961988/hill-country-wine-cave-clayton-korte

Hill Country Wine Cave - Frame Magazine, accessed May 28, 2025, https://frameweb.com/project/hill-country-wine-cave

Hill Country Wine Cave - Texas Architect Magazine, accessed May 28, 2025, https://magazine.texasarchitects.org/2023/09/01/hill-country-wine-cave/

Hill Country Wine Cave by Clayton Korte - RTF | Rethinking The Future, accessed May 28, 2025, https://www.re-thinkingthefuture.com/architecture/hospitality/10332-hill-country-wine-cave-by-clayton-korte/

Hill Country Wine Cave | Clayton Korte | Archello, accessed May 28, 2025, https://archello.com/project/hill-country-wine-cave

UC Berkeley drills 400-foot borehole to explore geothermal heating on campus, accessed May 28, 2025, https://news.berkeley.edu/2022/03/30/uc-berkeley-drills-400-foot-borehole-to-explore-geothermal-heating-on-campus/

Digging Deep: How Berkeley Lab Advances Subsurface Research for Energy, Water, and More, accessed May 28, 2025, https://newscenter.lbl.gov/2025/05/27/digging-deep-how-berkeley-lab-advances-subsurface-research-for-energy-water-and-more/

Why More Wineries Are Building Underground Wine Caves, accessed May 28, 2025, https://fdc-comp.com/building-underground-wine-caves/

Got Wine Cave? Paso Robles has several you can enjoy!, accessed May 28, 2025, https://elitewinetourspaso.com/2022/07/wine-caves-paso-robles/

Building the Modern Wine Cellar: Green Guide to Bottle Storage - VintageView, accessed May 28, 2025, https://vintageview.com/blog/2023/09/wine-cellar-green-energy-guide/

Hill Country Wine Cave - AZ Awards, accessed May 28, 2025, https://awards.azuremagazine.com/article/hill-country-wine-cave/

Positive Energy | Building Science Focused MEP Engineering, accessed May 28, 2025, https://positiveenergy.pro/

What We Do - Positive Energy, accessed May 28, 2025, https://positiveenergy.pro/what-we-do

Kristof Irwin, PE, M. Eng. - Positive Energy, accessed May 28, 2025, https://positiveenergy.pro/kristof

Reducing Data Center Peak Cooling Demand and Energy Costs With Underground Thermal Energy Storage | NREL, accessed May 28, 2025, https://www.nrel.gov/news/detail/program/2025/reducing-data-center-peak-cooling-demand-and-energy-costs-with-underground-thermal-energy-storage

Moisture control : r/buildingscience - Reddit, accessed May 28, 2025, https://www.reddit.com/r/buildingscience/comments/1fhf5q7/moisture_control/

BSD-012: Moisture Control for New Residential Buildings | buildingscience.com, accessed May 28, 2025, https://buildingscience.com/documents/digests/bsd-012-moisture-control-for-new-residential-buildings

Moisture Control For Buildings, accessed May 28, 2025, https://buildingscience.com/sites/default/files/migrate/pdf/PA_Moisture_Control_ASHRAE_Lstiburek.pdf

Info-101: Groundwater Control | buildingscience.com, accessed May 28, 2025, https://buildingscience.com/documents/information-sheets/groundwater-control

How and Why Rainscreen Walls Work, or When They Don't: - A Deep Dive into the Building Science, accessed May 28, 2025, https://rainscreenassociation.org/wp-content/uploads/2024/11/RAiNA-Conference-RDH-How-Rainscreens-Work-or-Dont-GF_FINAL.pdf

Passive Building Design Guide - Phius, accessed May 28, 2025, https://www.phius.org/sites/default/files/2022-04/phius-commercial-construction-design-guide.pdf

www.phius.org, accessed May 28, 2025, https://www.phius.org/sites/default/files/2023-11/Actionable%2C%20Cost%20Effective%20Passive%20Building%20Strategies%20-%20Ryan%20Abendroth%20phiuscon%202023.pdf

Passive House Design and the Phius Standard - Fine Homebuilding, accessed May 28, 2025, https://www.finehomebuilding.com/2024/11/11/passive-house-3-0

www.ashrae.org, accessed May 28, 2025, https://www.ashrae.org/file%20library/technical%20resources/covid-19/i-p_s16_ch22humidifiers.pdf

Achieving optimal air quality inside a wine cabinet. | EuroCave expert advice, accessed May 28, 2025, https://www.eurocave.com/en/eurocave-expert-advice/achieving-optimal-air-quality-inside-a-wine-cabinet

Standards 62.1 & 62.2 - ASHRAE, accessed May 28, 2025, https://www.ashrae.org/technical-resources/bookstore/standards-62-1-62-2